The crankshaft balancer hub that fits into the timing cover seal was a little worn, so I found out that they make crankshaft sleeves out of extremely thin sheet metal that are slightly smaller than the hub itself. A little grease, and you hammer it on.

Good to go.

To tap the timing seal in place, I bought an exhaust pipe adapter, covered it in blue tape to cut down the abrasiveness it may have.

Timing cover bolts with anti-seize.

Time to mount the oil pan.

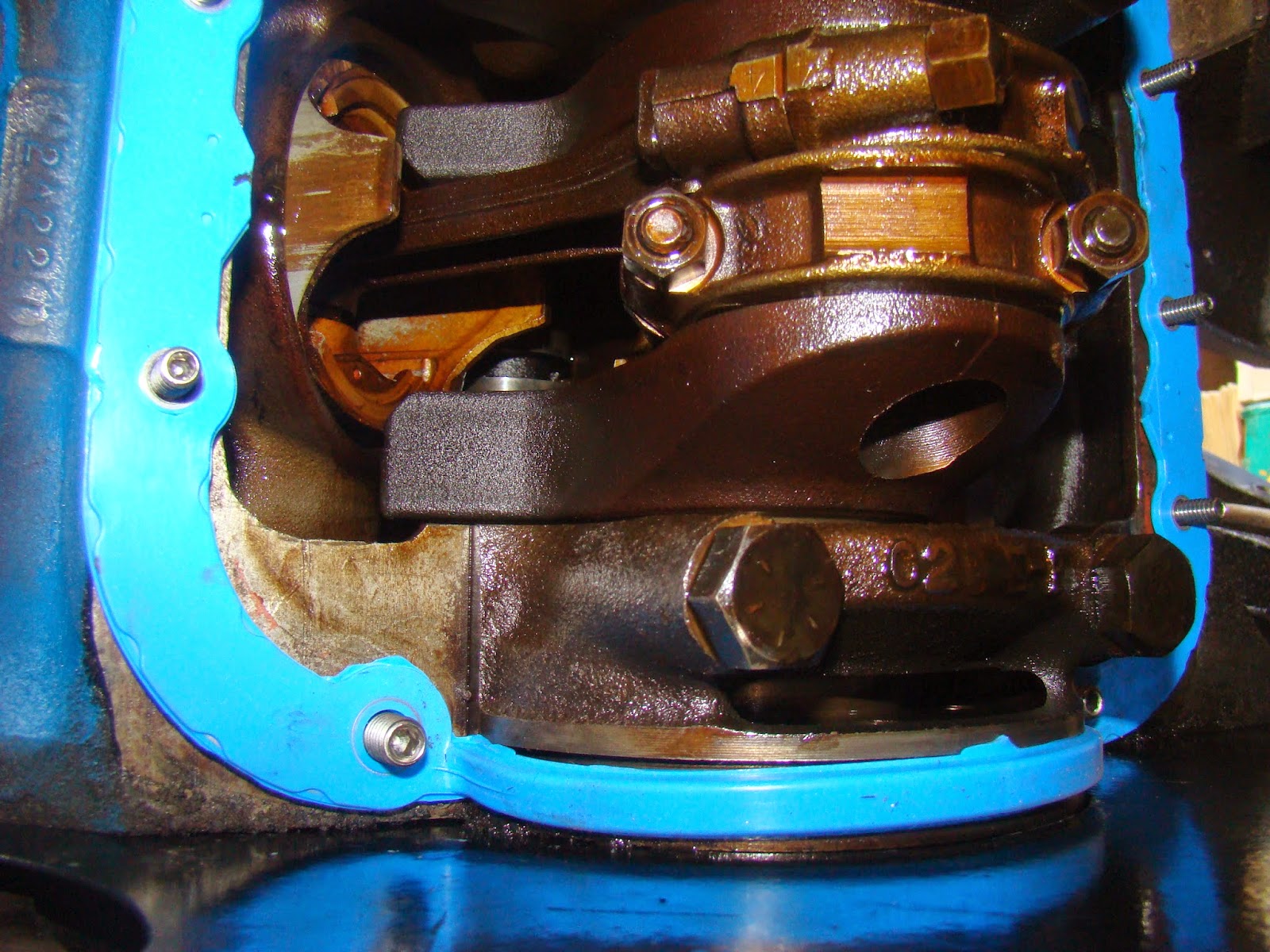

Here's the rotating assembly. No sludge. A nice sheen on everything. I'm pleased. (I may have a cylinder or two with low compression, but so be it for now.)

New, reusable gasket and studs instead of bolts. Both will make oil changes more friendly.

Fuel pump seal and RTV.

Pump on.

These intake ports are a bit crusty, so they'll need a scraping. I started by putting in some shop towels to keep crud from dropping down into the cylinders.

Scraped clean and the lifter valley vacuumed.

They aren't perfect, but they are better.

Gaskets in.

Intake set in place. Much easier to do with no fenders or grill in the way. That way, I could go straight down without worrying about the gaskets moving.

Pulley in place with grade 8 hardware.

After my boy and I got the water pump in place, we went to work on the alternator. It's a GM one-wire alternator, but I was able to use a Trans-Dapt 9455 bracket for a small block Ford engine (though supposedly it wouldn't work with a 260, but it did).

Steel tubing (leftover from the hinges I made for the tool box lid that sits under the passenger seat in the tub) made the alternator mounting solid and stiff.

Done.