Started with the rear suspension.

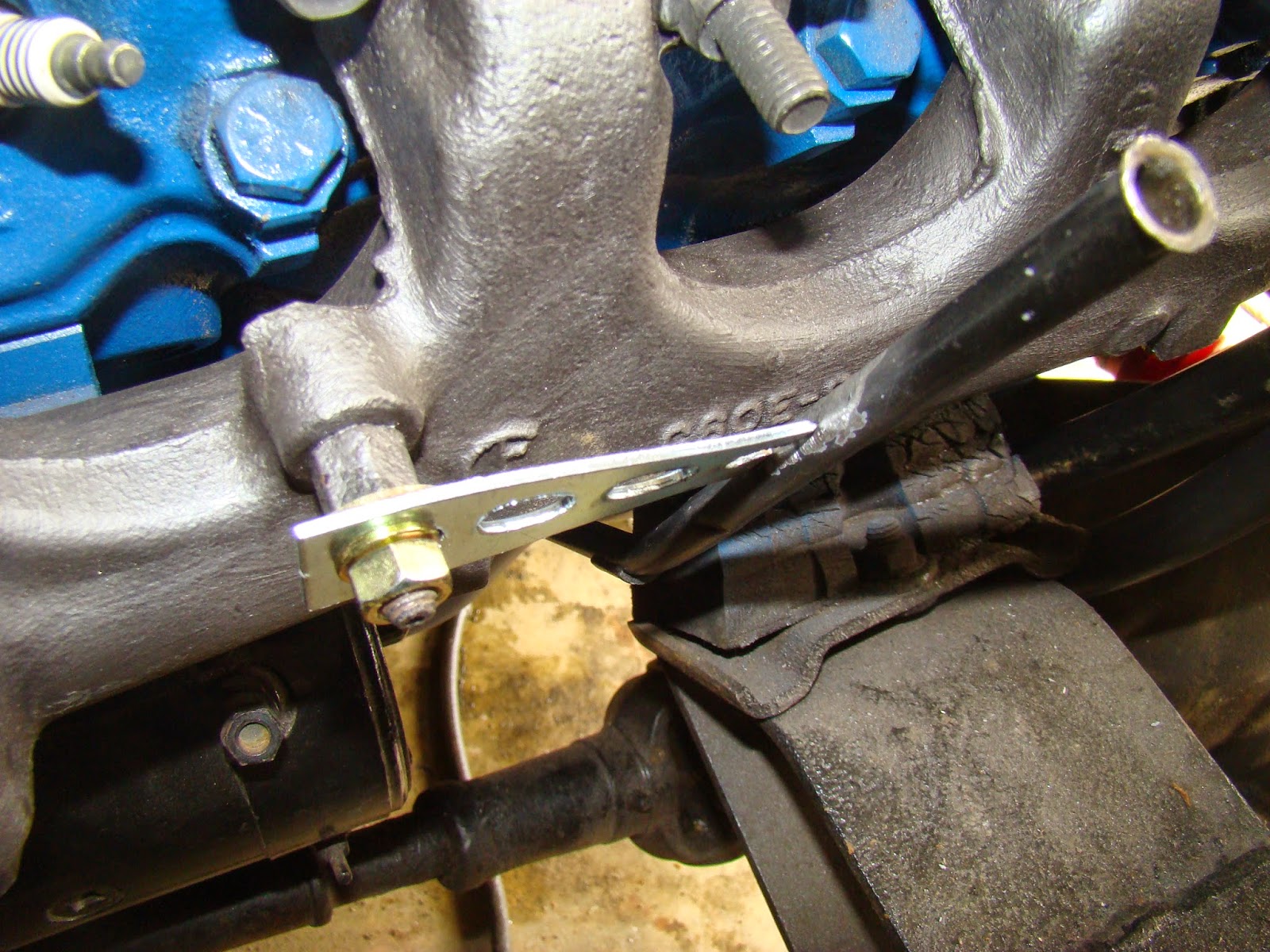

Made some new shackle plates. I'll keep them for now, but I'd like to upgraded to TeraFlex Revolver shackles, which are wicked cool. The project came with these stamped ones, but they were too thin (less than an 1/8" thick) and the holes were wobbled out of round. Rather than buying new ones, I just bought some 1/8" thick mild steel strips and made my own. In hindsight, not worth the effort, but I was trying to save some cash.

Marked them out.

Clamped together. While they aren't all exactly the same length, the holes will be equidistant.

I rounded the edges and drilled the holes on my drill press, then primed them.

Black enamel.

On.

Moving on to the front suspension, which is more complicated. Tires off. He's a whiz with the air gun.

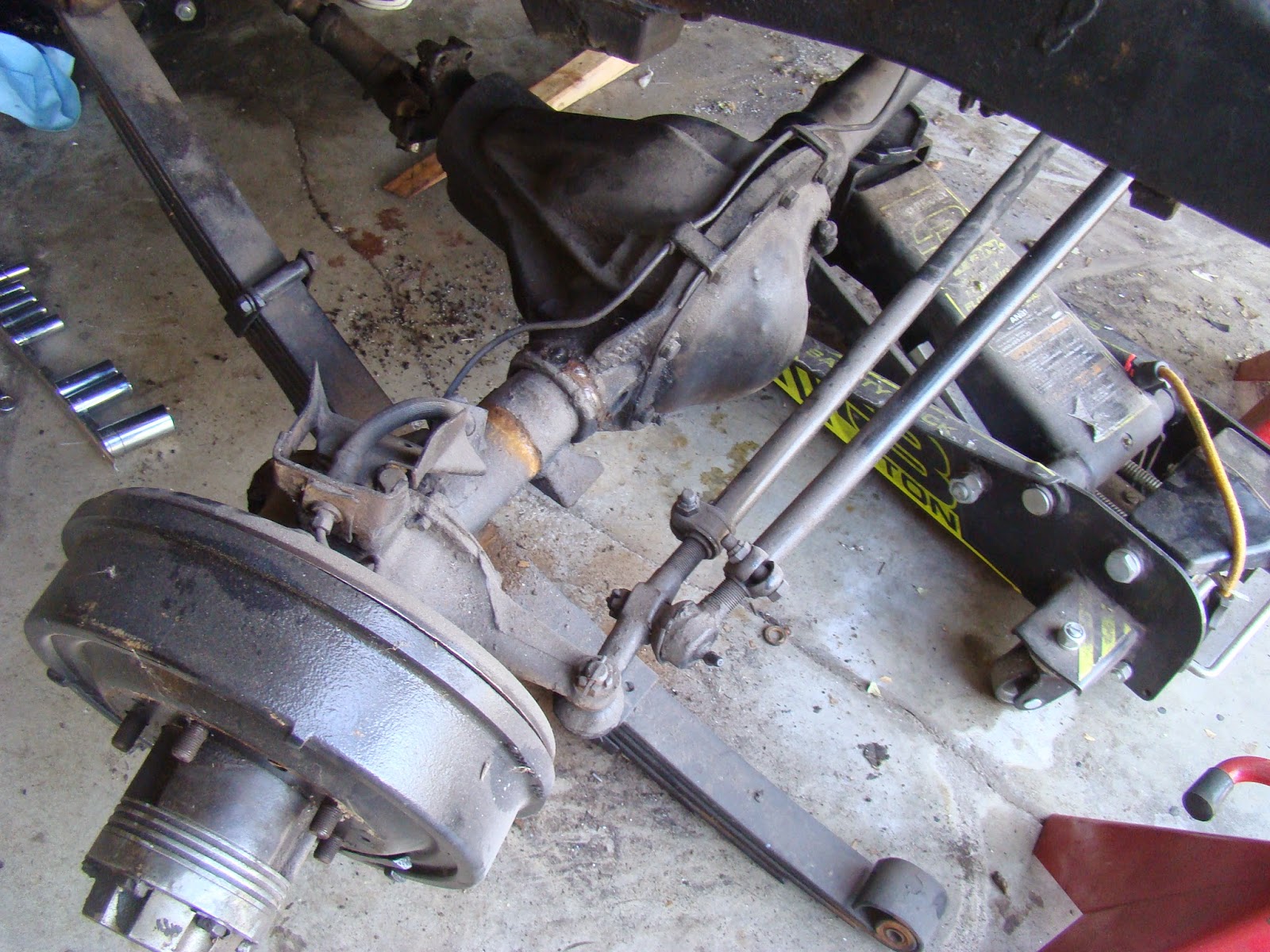

Pulling the Dana 25. I'm pushing its limits with 31" tires, and I'm not impressed with drum brakes up front. So I've been looking on Craigslist for a Dana 30, and I finally found a narrow track CJ7 front axle with 3.54's. It came with an AMC 20, which I'll be selling on, along with the Dana 25.

Out.

These original springs don't have any lift, and they have about ten leaves, which will make them stiffer than I want.

But for now, they stay. Rancho 2.5" springs are on their way.

I'll be replacing the steering stabilizer, but the brackets are still good.

My wife. I can't even describe how supportive she is of me and my project. She knows it's for my mental health, and she doesn't sweat the monthly money drain at all.

The discs. No real damage on the discs, which is great. I'll just give them a good cleaning.

The bushings are shot. I needed to pull them out, which required some tools.

Gunky. These greasable bolts are going to be replaced with grade 8 bolts.

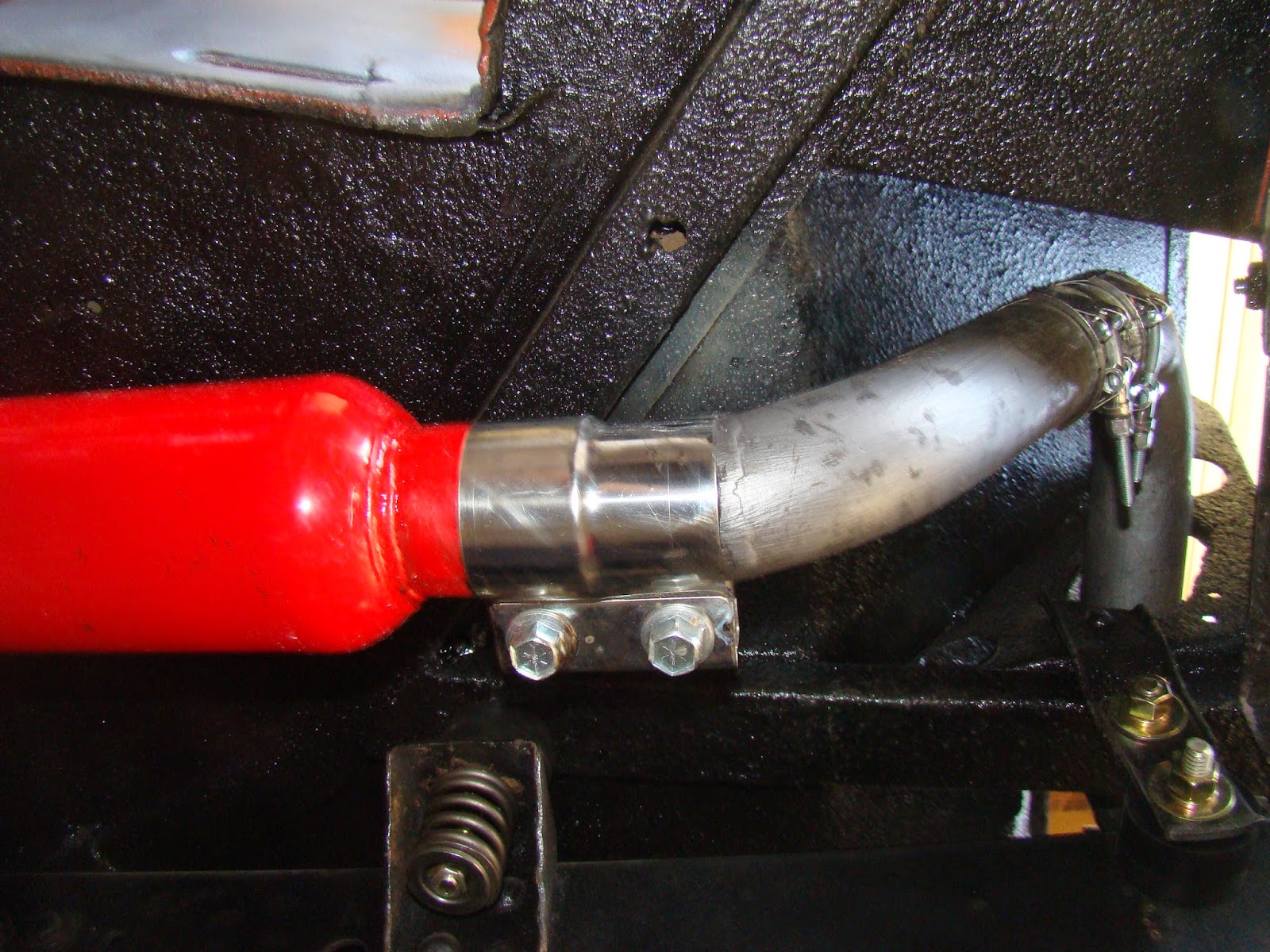

The Rancho springs are here. Color me happy.

The homemade spring plates that came with the project are less than impressive, but I'll keep them on for now. Once the rest of the rig is road ready, I'll get good ones in place. In order to make these work, I had to widen and/or elongate the holes, getting awfully close to the plate edge. The back axle ones are worse (the shock mount is bent).

This section of frame rail on the passenger side is boxed, and the bolts are completely rusted in place. I just cleaned part of the rail and welded the bump stop extension bracket in place. I'm pleased with the welds, actually.

The driver side was easier to attach. I just chased the threads of the captured nts and bolted them in place. Here's a pic of a shot bump stop.

I added a new steering stabilizer shock, using the brackets that came with the Dana 30.

The original Dana 25 was a nice close fit.

Unfortunately, the classic steelie rims I have won't fit over the disc calipers, so I need to add spacers.

Originally, I bought 2" spacers. They were too much.

The 2" spacer.

So I dropped down to 1.5" spacers. I kept the 2" spacers for the back since the CJ3A Dana 44 is narrower in stock form than the CJ7 narrow track Dana 30. The alignment works well.

This sadness is what happens when someone with more practicality than sentimentality cuts up an original steering wheel to mount an Grant monstrosity.

So I got this one off of eBay for $50 bucks shipped. It's an original with a bit of cracking, which to me is better than a reproduction in perfect shape. It fits the vibe of the rig.

The steering column is slightly bent with a bearing welded to one end. It'll have to do.

Cleaned up and primed.

I did some research on steering columns and figured out I could use some of this scrap phenolyic plastic I had to make some centering bushings.

The stages.

This is the end of a new CJ3A steering shaft with the worm gear cut off. I slid the splined shaft up inside (perfect fit) and drilled some holes to weld them together.

Welded up and grinded smooth enough for me.

Shaft meets column and bushings.

More parts that came with the rig. I will massage them to get them to work with the column and steering shaft.

And the rag joint and universal joints all together.