The exhaust routing is problematic for obvious reasons: a big Ford V8 in a little Willys CJ3A.

Here's one of the two pipes that came with the project. Rusted quite extensively, but I tried to salvage them both.

The end is a bunch of overlapping bits, and I ended up trying to make even more layers as patchwork quilt of crappy metal and booger welds.

Even cleaned up, it's just a wrinkled and rusted mess.

A patch pipe.

I cut off the original flange with the hope that I could get a 2" pipe on there instead, which is a more standard size.

Man alive was I trying to chase good metal to get the new pipe mated to the old pipe.

But this is what I had to deal with. Any heat at all burned through the thinned, rusted metal.

So then I tried a patch over that. Ridiculous.

Since that wasn't working, I cut the other pipe off (no amount of liquid wrench, heat, and torque could do the job).

Notice the difference. The bottom one, off which I cut the rusted pipe, has had the flange cut off and rewelded. I'm going with the stock Mustang driver's side manifold (which, again, came with my project).

As much as I wanted these to work, they just had too much rust to be viable. So I cut the flanges off and went to welding school.

First, I had to install the stock Ford Mustang exhaust manifolds so that I could route my new exhaust pipes. Red RTV to seal them up.

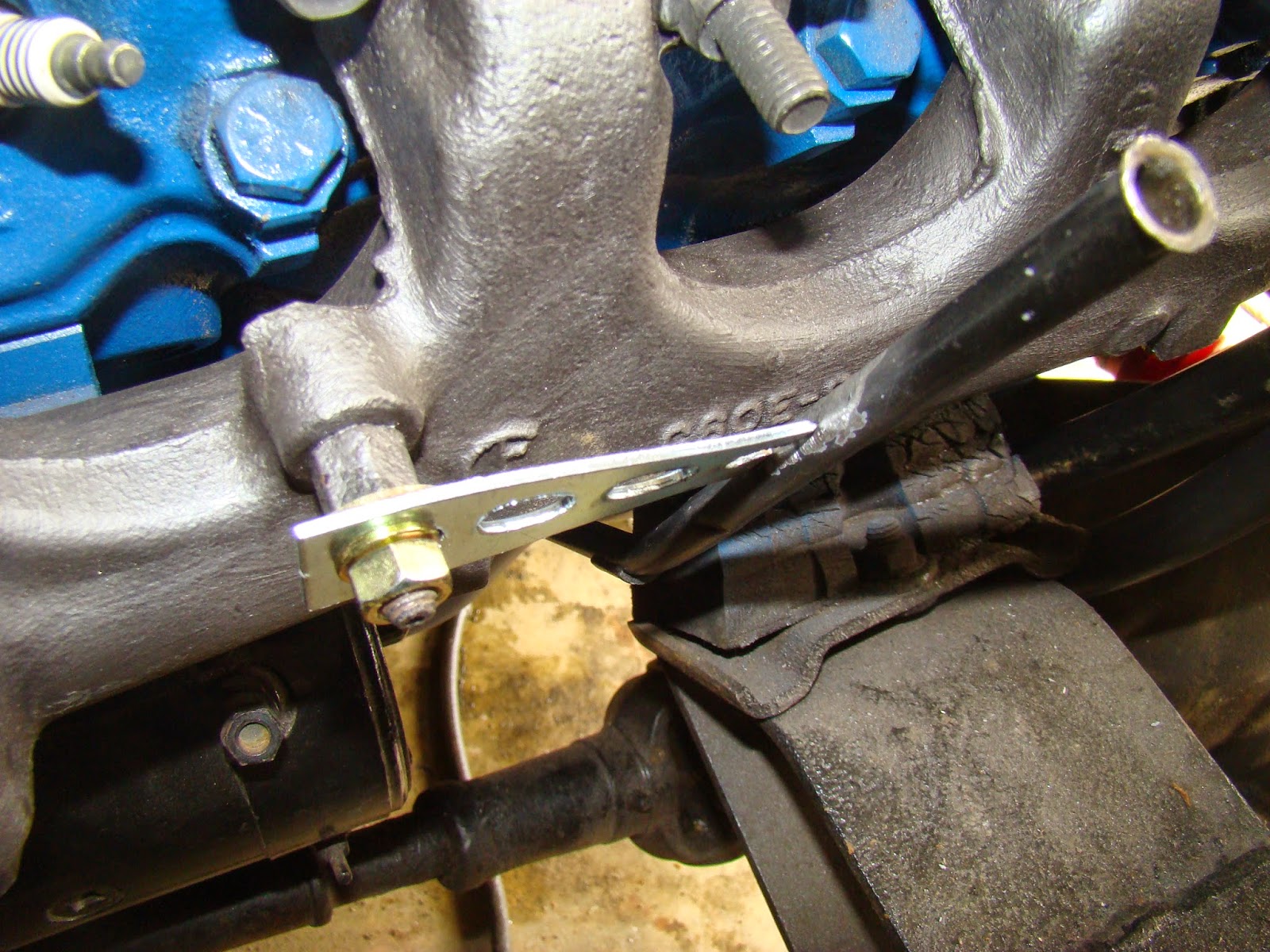

This is the driver's side, which is going to be the hardest routing path. Note the end of the steering column quite close by.

To get from the exhaust manifolds to the mufflers, I bought a bunch of J tubing and started cutting them up and welding them together to route from the stock exhaust manifolds down around the steering, up over the frame rail, down under the tub in front of the firewall, and then along the outside of the frame rail before dumping out in front of the rear tires, on both sides.

Yes, they are quite curvy and a little rough in my welding, but the tubes themselves are larger in diameter than the ones that I started with, and rust free.

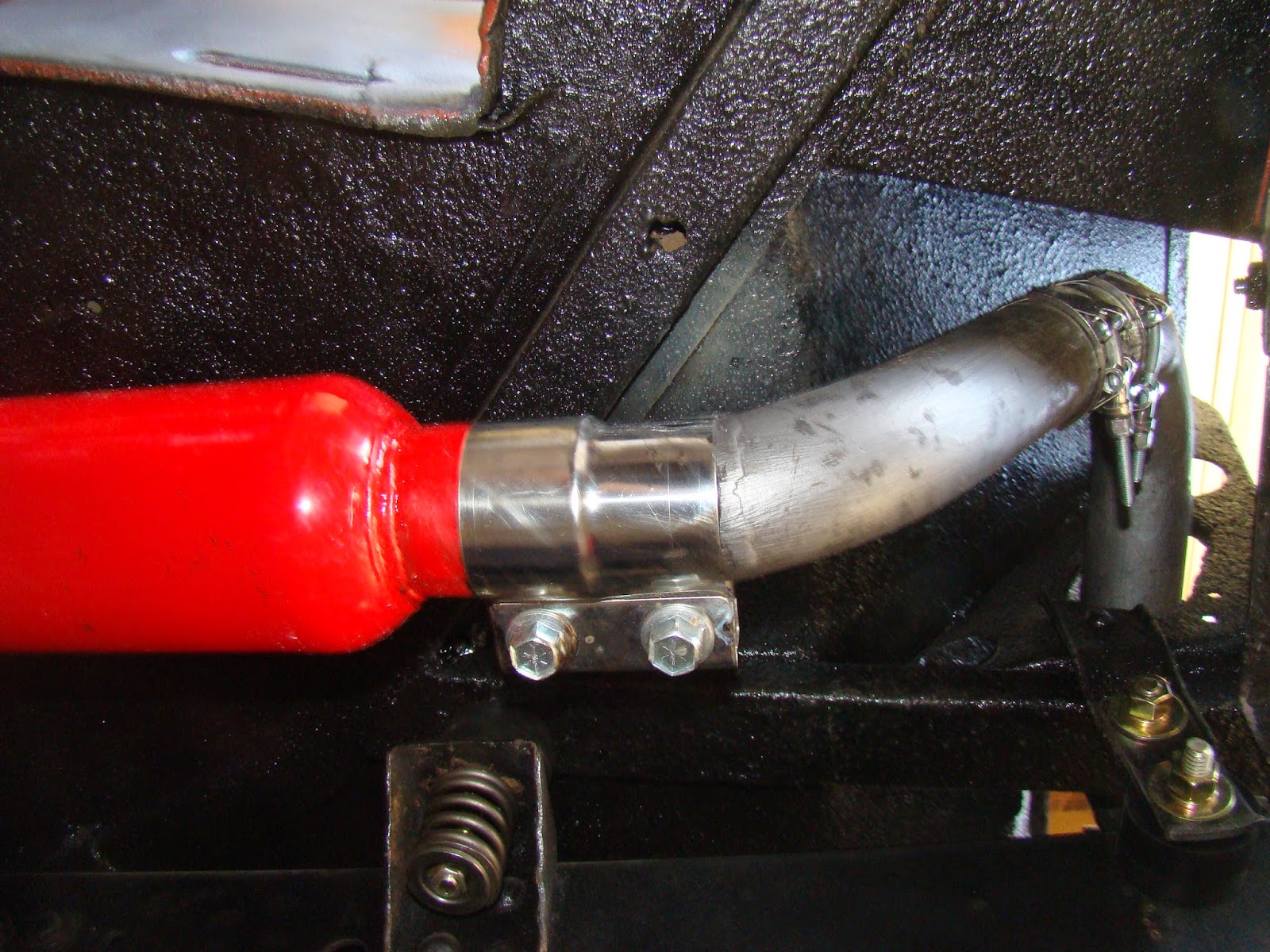

For mufflers, I went with Cherry Bomb glass packs. I want the rig to be a bit hot rod.

In order to install and remove the tubes as needed, I had to go with heavy duty band clamps, which I think will work out. I'm not terribly concerned if there are tiny leaks in the exhaust system since the engine won't work with a catalytic converter (it's a '63) and it'd be hard for the exhaust to harm me in a wide open Willys CJ.

Here you can see the passenger side routing as the tubing goes through part of the firewall support bracket.

Driver's side routing underneath and behind the steering column and linkage.

Looks good, doesn't it.

I needed to paint the tips and I had the gold left over from the valve covers, and I like the look. Also, note the mounting bracket.